Highlight

zeropex hydrogen fuel parks

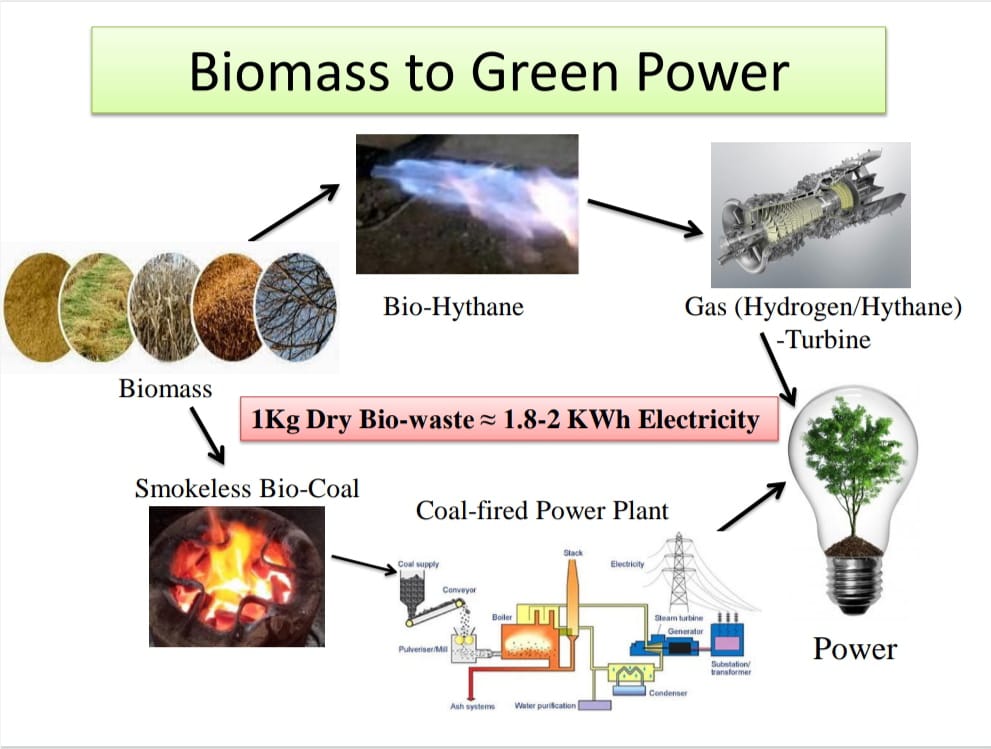

The distinctive output (Hydrogen 3-4%, Methane or Natural Gas 12-14%, and Bio-Coal 25-28%) from Biezel TAD Reactors make the technology Cost and Power neutral.

The Methane or Natural Gas produced by TAD technology is more than enough to cover the power needed to run the reactors and other required units. The cost of Bio-Coal can easily manage the operational charges. Thus at "Zero Operational Cost (ZEROPEX)", Biezel can produce surplus Hydrogen and other biofuels.

To Know more:

Products

Laboratory grade to Ultra-High Pure Hydrogen.

~75% Hydrogen balanced in CNG. Commonly known as H-CNG.

Biezel offers CNG in the liquified form.

CNG (Methane content >95%) and Methane Laboratory grade to Ultra-High Pure grade.

Purity up to 99.5%.

GCV > 7500 cal/g

GCV ~ 6500-7000 cal/g

GCV ~ 5500-6000 cal/g

Anti-rust paint

Can be utilized inroad making and similar applications.

Excellent pesticide and fertilizer that improves soil quality, helps elimination of pests and assists in the plant growth.

Heavy Industry Solutions

Hydrogen or Hydrogen-rich gas turbines have many environmental and economic benefits. Such turbines can be fitted into existing power plants and can run on less pure forms of hydrogen, which can be carried in any form, from liquid hydrogen to ammonia. Biezel's capability of producing Hydrogen or Hydrogen-rich gas is unmatched and ready to associate with turbine entities to bring clean and green power generation solutions to the world.

Biezel's Hydrogen-rich gas has High Energy Density free from corrosive gases such as NOx, SOx, and Low Carbonaceous exhaust. Owing to the high energy density and large H2 content, it can be used as high-energy fuel in gas-based blast furnaces, especially for the Ceramic, Glass, and Steel industry. High-temperature value makes it useful for the clean production of Glass, Steel, Cement, and Ceramics.

World is looking for the solutions to utilize Hydrogen or Hydrogen-rich gases in majority and for this various R&D work is going on. Biezel TAD reactors convert 16-17% mass into Bio-Hythane. The required amount of Hydrogen or Natural gas can be mixed with Biezel's Bio-Hythane to make it fit for utilization.