BIEZEL GREEN ENERGY

How It all Started!

PROBLEM STATEMENT

Due to the continuous rise in power/fuel demand to fulfill society's energy demand, there is a constant rise in fossil fuel intake that is causing a sudden price rise of the fuel, and depletion of fossil fuel is also an issue. Further, the environmental concern due to the release of toxic exhaust and greenhouse gasses from the burning of fossil fuel and the increase in net carbon in the earth's environment causing global warming at an alarming rate is also a serious issue. As a mandate of the Paris Climate Accords 2015, there is pressure on the governments to decrease fossil fuel usage and carbon footprint. In the wake of the current fuel crisis and environmental norms, there is a sudden push for the hydrogen economy, as hydrogen is a clean fuel, and the fuel's exhaust is water.

THE SOLUTION

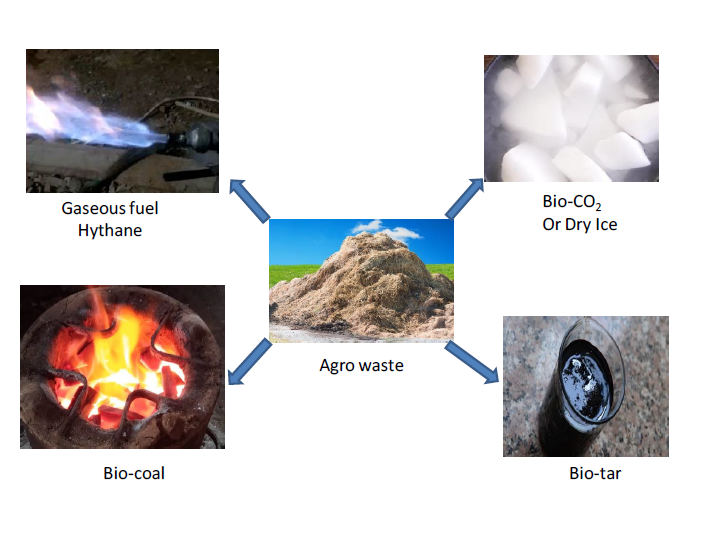

The solution is Biezel's TAD reactors, in which an environment similar to the earth’s crust is created to convert bio-waste into useful fuels. In Biezel’s TAD reactors, the process of converting biomass into fuel, which takes millions of years, can be completed in a day. In addition, net carbon neutrality can be achieved in one cropping season.

The Technology

Biezel`s electrically powered Thermochemical cells (TAD Reactors) utilize 10MT biomass in a one-time operation of 96 hours. The TAD reactors are electrically powered and equipped with in situ Water Gas Shift (WGS) catalysis. No external water requirement for the processing conversion of biomass into biofuels. Almost 60 hours are running/operation, and 36 hours is shut down time for cooling and cleaning (removal of Bio-coal) and recharging the reactors with biomass. TAD reactor needed 25 kWh of power to operate.

TAD exhaust (Biezel Bio-Hythane; BBH) after CO2 scrubbing from the TAD reactor contains 65-75% Hydrogen containing Methane or Natural Gas with HHV close to 64-76 MJ/Kg. Then BBH is separated into UHP Hydrogen and LNG through our indigenously developed Cryo-separator. The indigenously designed Cryo-separator involves Hydrogen's high heat conducting property to separate it from Hythane or BBH using a well of Liquefied Nitrogen.

Fuel composition is highly dependent on the type of raw material used.

The Process

mimicking the earth crust's process of converting fossils into fuels

BIEZEL Proposes...

Environmental protection is a social movement. The protection of the environment has assumed even more importance in recent times with increased industrialization resulting in the overdraw of natural resources and pollution of air, water, flora & fauna. While development is essential to every economy, it is also necessary that no irreparable damage be caused to the ecosystem.

In addition to environmental protection, Biezel also proposes ex-situ stubble and Agro-forestry waste management to counter stubble burning. With the higher fuel conversion efficiency of TAD reactors, Agro-forestry waste can be collected at fair prices. As one acre of land generates about 2 MT of crop residue (Source: Down to Earth), farmers can get additional income from the agricultural residue or Agro-forestry waste. TAD reactors can process these residues of all the crops grown in the state: bagasse, wheat, rice, cotton, sugarcane, pearl millet, maize, barley, fruits, coconut, lentils, etc.